Kajima and PFN Develop Autonomous Navigation System for Construction Site Robots

TOKYO – March 4, 2021 – Kajima Corporation (Kajima) and Preferred Networks, Inc. (PFN) have jointly developed a safe and robust autonomous navigation system, tentatively named iNoh, for industrial robots at construction sites. As the new system’s first application, the companies have introduced an iNoh-powered autonomous cleaning robot in Kajima’s sites in the Tokyo metropolitan area. Kajima and PFN plan to use iNoh for other purposes at building construction sites such as surveillance and material carrying, and also adapt the system for other industries in the future.

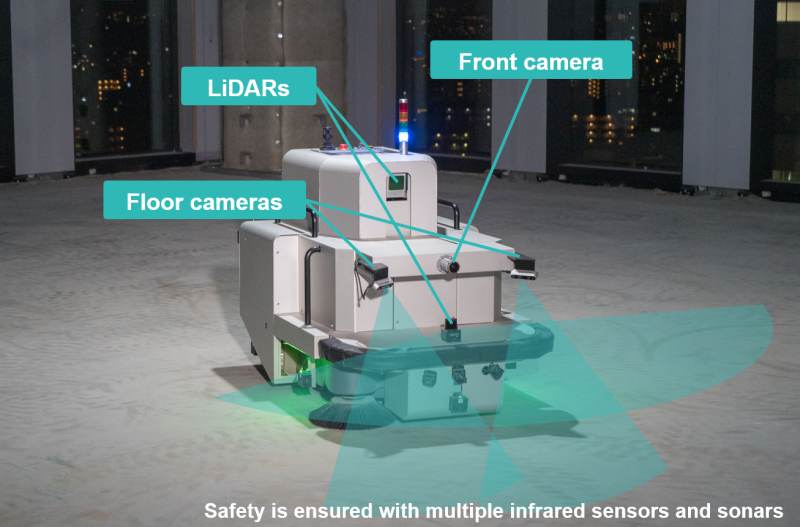

Autonomous cleaning robot equipped with iNoh

Autonomous cleaning robot equipped with iNoh

Developed to meet automation needs at construction sites with frequent changes, the iNoh system enables robots to locate themselves and recognize their surroundings safely and accurately in real time without the need for a global navigation satellite system (GNSS) or manual configuration.

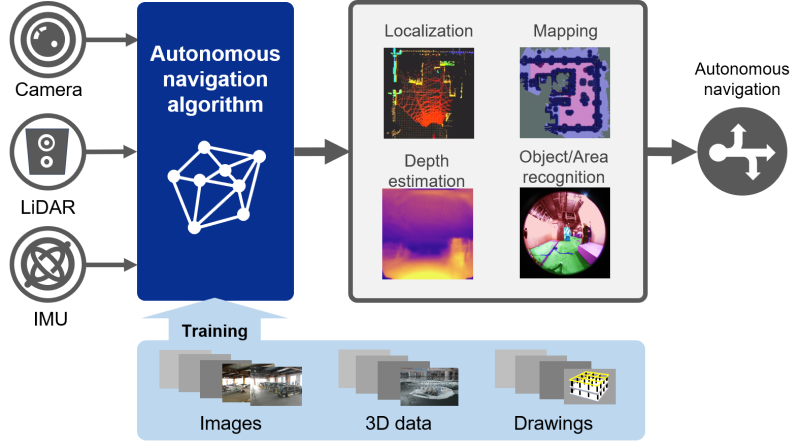

The iNoh system is characterized by the following features.

1. Multi-sensor simultaneous localization and mapping (SLAM) technology

Real-time data from the cameras, LiDARs and inertial measurement unit (IMU) are integrated to enable the robot to locate itself accurately in a 3D map of its surroundings even in a non-GNSS environment with frequent changes.

2. Advanced environment recognition based on deep learning

The system robustly and accurately recognizes obstacles, moving vehicles, no-entry zones and workers based on a deep learning model trained with actual construction site images.

3. Real-Time Navigation

The robot can be operated immediately without manual configuration as the system recognizes its location and surroundings, and generates routes in real-time to avoid obstacles.

iNoh autonomous navigation system

iNoh autonomous navigation system

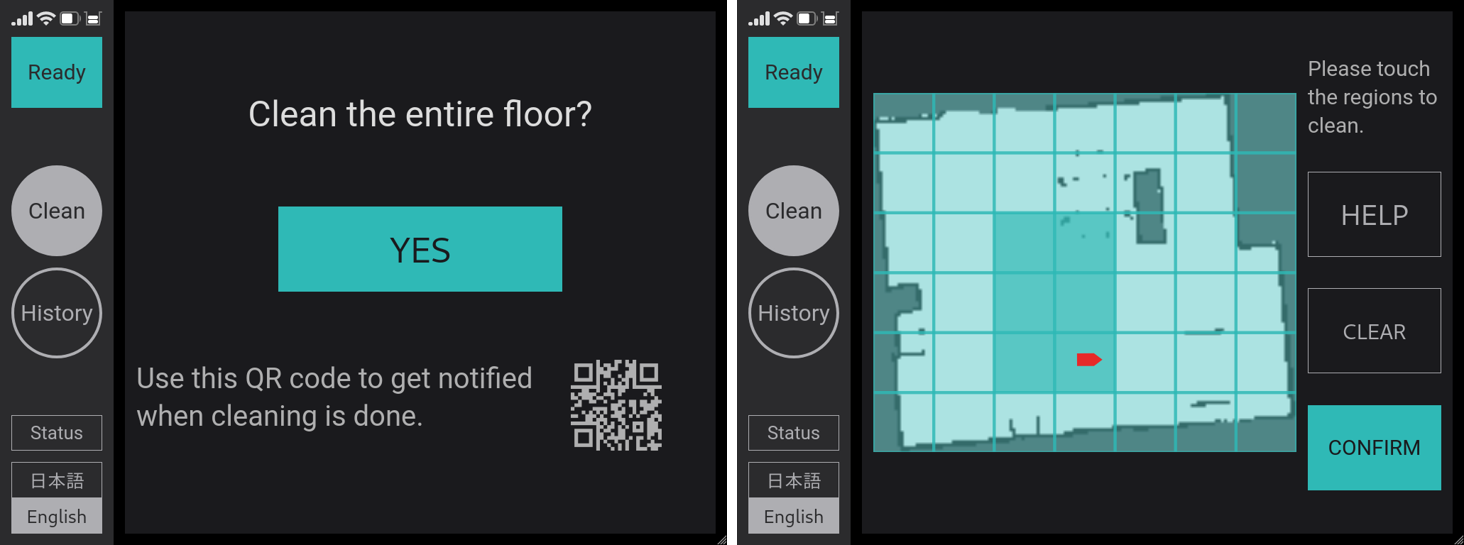

Kajima and PFN have also jointly developed an iNoh-equipped floor cleaning robot for construction sites. Tentatively named Raccoon, the robot can clean the concrete floor with as few as three taps on the attached touchscreen. The companies have verified the practicality of the iNoh system after testing Raccoon in multiple sites in the Tokyo metropolitan area, where the robot was able to operate for 100 consecutive minutes to clean approximately 500 square meters. Raccoon is able to operate in two modes:

Automatic cleaning mode

The robot automatically explores cleanable areas without maps or user instructions.

Area cleaning mode

The user can set a specific area for cleaning after the robot generates a map of the cleanable areas.

Sensors equipped on the Raccoon cleaning robot

Sensors equipped on the Raccoon cleaning robot

Raccoon control screens

Raccoon control screens

(Left: Automatic cleaning mode / Right: Area cleaning mode)

Kajima and PFN started joint research in 2018 to solve existing problems in construction site automation. Since then the two companies have collected construction site images, 3D data and drawings, used them to train deep learning models and repeated trial-and-error processes in actual sites to co-develop iNoh. Kajima and PFN plan to continue enhancing the system’s environment recognition accuracy with additional data.