News

ENEOS and PFN Succeed in Autonomous Operation of Petrochemical Plant Using AI Technology

New AI system automates operations currently performed by skilled operators

2021.12.02

TOKYO, December 2, 2021 – ENEOS Corporation (ENEOS) and Preferred Networks, Inc. (PFN) announced today that they have succeeded in operating a butadiene extraction unit autonomously in ENEOS Kawasaki Refinery’s petrochemical plant for two consecutive days using a new artificial intelligence (AI) system. Jointly developed by ENEOS and PFN, the AI system automates large-scale, complex operations of oil refineries and petrochemical plants that currently require operators with years of experience.

The two companies expect the AI system will help them improve safety and stability of plant operations by reducing dependence on technicians’ varying skills levels. ENEOS’s research has shown that the two-day trial is the first successful case in Japan of an AI-enabled autonomous operation at an actual petrochemical plant.

ENEOS and PFN’s joint effort to build an autonomous plant operation system started in 2019 with a strategic alliance formed in response to the growing concern around shortage of human resources due to the aging of skilled operators with manual operation experience. Currently, oil refineries and petrochemical plants are monitored and operated by such operators on a 24-hour basis.

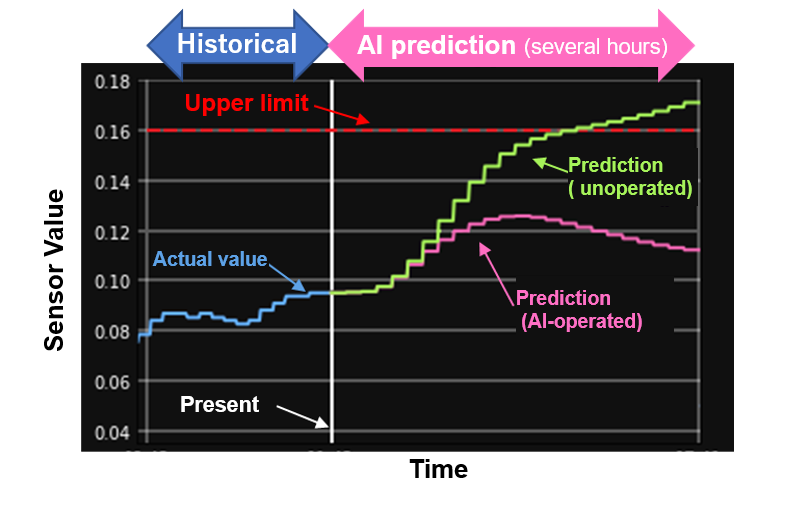

The AI system is designed to predict the plant unit’s future sensor values and valve operation requirements based on past data of complex correlations between multiple sensor values and valve operations, supplemented by simulated data. During the successful two-day trial with the butadiene extraction unit, the AI system continuously monitored 25 important factors, including internal temperature, pressure, flow rate and product conditions, while it autonomously adjusted 12 valves.

The development of the AI system is supported by 2020 subsidies from Japan’s Ministry of Economy, Trade and Industry.

ENEOS and PFN will continue their trials with the butadiene extraction unit to achieve stable operations that are unaffected by technicians’ skill levels, and subsequently extend its use to other major plant units including crude distillation units on the same site and other refineries. The companies also aim to implement a new AI-based autonomous plant operation model that can increase production and energy efficiencies.

Through this collaboration, ENEOS and PFN will also support the United Nations’ Sustainable Development Goals including Goal 9 (“Build resilient infrastructure, promote inclusive and sustainable industrialization and foster innovation”).

Change in important factor (Example: Sensor value for product property)

The AI system had predicted that the sensor value would exceed the upper limit if unoperated (green); the system automatically operated the control element to keep the value within the prescribed range (pink).